Fill out the form, and a 1st Choice Fire Protection specialist will contact you.

"*" indicates required fields

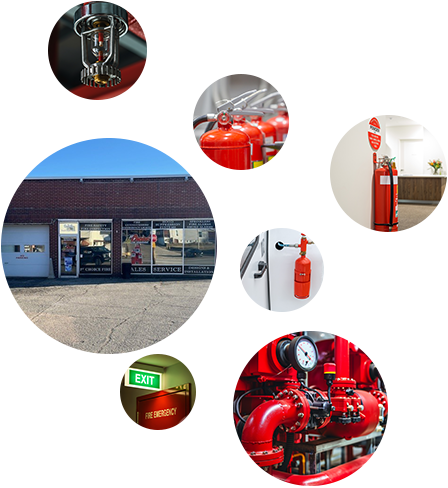

One partner for fire protection systems and equipment across Eastern Ohio (St Clairsville to East Liverpool), Western PA (Pittsburgh to Washington), and West Virginia (Wheeling area to Morgantown). We support commercial and institutional facilities with sales, installation, inspections, service, maintenance, and repair.

1st Choice Fire Protection is a local Ansul distributor serving commercial facilities across Eastern Ohio, Western Pennsylvania, and Northern West Virginia.

We install and service Ansul wet chemical kitchen suppression systems, including semi-annual inspections, routine maintenance, and emergency repair support. Our inspection process evaluates system components and required service intervals to help facilities maintain compliance and documented protection.

As a distributor, we provide manufacturer-aligned equipment, compatible replacement components, and ongoing system support for commercial kitchens and institutional food service operations.